Microminiaturization

5.1.9.

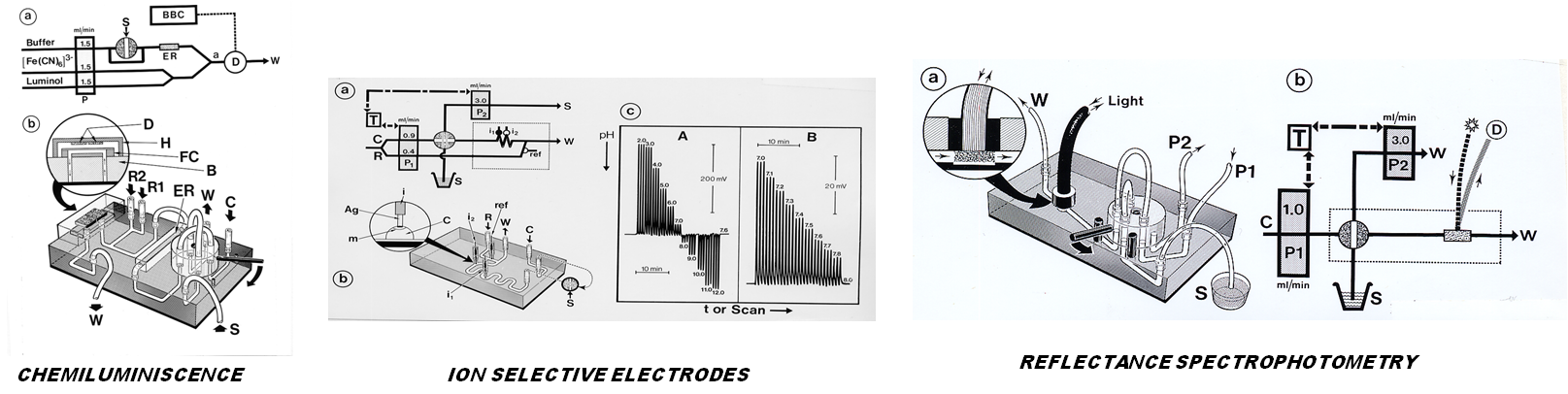

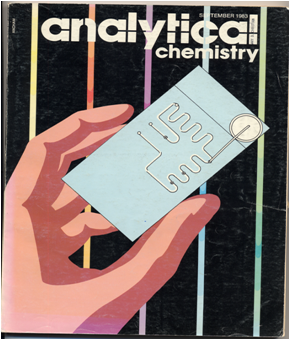

The trend toward downscaling of chemical assays began in the 1930’s by works of Pregl, Bennedetti-Pichler and Feigl, and accelerated rapidly toward the end of the last century. Since conventional FI was based on continuous pumping, it was desirable to decrease reagent consumption by downscaling the flow system. We achieved that by integrating the injector, reactor and detector within a single unit the size of a credit card. [441,608] The flow channels were embossed in a rigid PVC plate and sealed with an adhesive polymeric sheet. These modules used chemiluminescence for enzymatic assays, potentiometry for pH measurements, CHEMFETS (with Art Janata) for potassium and chloride assays. Modules for reflectance spectrophotometry used bifurcated optical fibers interfaced with a layer of immobilized indicator. Although somewhat innovative, the idea never caught on. It was 20 years ahead of its time.

The purpose of bringing up this subject is not to grumble, but to cast some light on the process of inventing. A “person skilled in art” (to use the patent lawyer’s wording), and familiar with the technology available in 1983 should be able to visualize the principle of “Lab-On-Valve” design from the drawings shown below. Yet this is not correct, because in 1983, programmable flow was not conceived, the essential hardware components of LOV design including software did not exist. Therefore the process of inventing is usually not a flash of inspiration, but it requires years of patient groundwork. During that time, some concepts may appear and reappear, but they can bear fruit only when the supporting technology and materials become available.